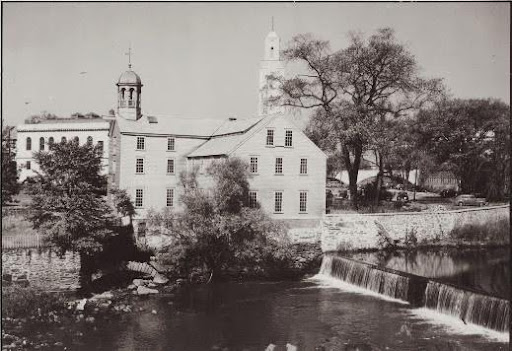

Over 230 years ago, Samuel Slater ignited a revolution that changed the course of manufacturing in America. In 1793, Slater established the first successful water-powered cotton spinning mill in the United States, harnessing the power of the Blackstone River to mechanize textile production. This innovation marked the birth of America’s factory system and transformed Pawtucket into a hub of industrial activity.

Just over a year ago, Amerisewn relocated its cut and sew manufacturing facility to Pawtucket, Rhode Island, the very city where American manufacturing set its roots. Situated on the second floor of an old mill building, just below Northeast Knitting, our facility maintains the spirit of innovation and craftsmanship that has characterized this region for over two centuries. This historical location reflects our connection to America’s manufacturing origins and our alignment with Slater’s legacy of cutting-edge manufacturing innovation.

Building Excellence Through Strategic Partnerships

Amerisewn is not your average cut and sew. As a specialized contract sewing manufacturer, we’ve built a reputation for manufacturing complex, high-performance sewn products. Our expertise covers military applications, healthcare solutions, and any industrial textile manufacturing services, for clients who expect top-tier quality.

Carrying Slater’s vision of innovation and trailblazing, we foster strong, collaborative partnerships – especially in research and development. Our customers are our partners in innovation, whether for military product development or custom cut and sew, the potential for product innovation is amplified. Our specialties lie in the manufacture of functional wearables for the U.S. military, high-quality consumer products, protective pads for healthcare workers, and any relevant industrial sewing services.

The Modern Manufacturing Revolution

Amerisewn’s 30,000 square foot facility (with another 30k ready to expand) houses recent investments in modern industrial sewing manufacturing equipment as well as the build out of a secure manufacturing space within the facility, also known as our “Manufacturing Innovation Lab”. See the full scope of our equipment here.

Cutting Systems

- AutoMetrix digital cutting system for scaling the manufacture

- Two 64” laser cutters for consistent precision on delicate fabrics

- Hydraulic clicker and traveling head presses for consistent results

Sewing and Assembly:

- Programmable automatic pattern sewing machines that ensure consistency

- Heavy-duty lockstitch and specialized industrial equipment

- Multi-material integration capabilities including electronics, foams, and plastics

- Lamination system

- Heat presses and seam sealers for multi-material integration

Quality and Finishing:

- Comprehensive quality control processes

- Flexible packaging and shipping solutions

Engineering Solutions Through Process Innovation

Just as Slater revolutionized production methods in 1793, Amerisewn continues to advance American manufacturing through process innovation. We consider the volume, timelines, and unique construction of your project to create a tailored manufacturing line to optimize efficiency and quality. Our approach integrates traditional craftsmanship with modern engineering principles and of course we are always learning from our customers and staying on top of industry best practices.

Our comprehensive manufacturing process includes:

- Product Development – We work hand-in-hand with you to turn ideas into reality

- Material Sourcing – Leverage our extensive network to find the perfect materials

- Process Development – Creating optimized manufacturing workflows

- Cut & Sew & Assembly – Integrating textiles, foams, plastics, and electronics

- Quality Control – Quality Control checks at every step of the manufacturing process

- Pack & Ship – Coordinated packing and distribution services

Specialized Expertise in Critical Applications

Our focus on military wearables and protective equipment has established Amerisewn as a trusted partner for government sewing contracts and defense applications. As domestic contract sewing manufacturer, we maintain full Berry Amendment compliance, ensuring all military products are manufactured using domestic materials and labor.

Military and Defense: Tactical gear, protective equipment, and specialized wearables designed for extreme conditions and critical applications.

Healthcare: Protective pads and functional gear that meet stringent safety and performance requirements.

Industrial Applications: Premium upholstery, custom covers, lift bags, and specialized textile solutions for demanding industrial environments.

Consumer Products: High-performance outdoor gear, functional accessories and premium quality bags, pouches and backpacks.

Whether you need 50 specialized tactical helmets for special forces training or full batch cut and sew textile manufacturing for high-quality made in USA consumer products, we approach each project with the same level of dedication and attention to detail.

In the same way that Slater’s mill revolutionized American production methods and labor systems, Amerisewn embodies a commitment to innovation, quality, and community. New equipment acquisitions, continuous improvement initiatives and team training programs are ensuring we stay ahead of the curve.

As we expand our capabilities and grow our team, our company’s mission reflects the industrious attitude that has been a hallmark of Pawtucket’s manufacturing legacy for over two centuries.

For information about Amerisewn’s manufacturing capabilities and partnership opportunities, contact us at info@amerisewn.com or call 401-223-0252. Let us help you bring your vision to reality through American manufacturing excellence.